INNOVATIVE FOCUS

PLM – Product Lifecycle Management / PDM – Product Data Management

PMP Otomotiv Sanayi Ticaret Anonim Şirketi

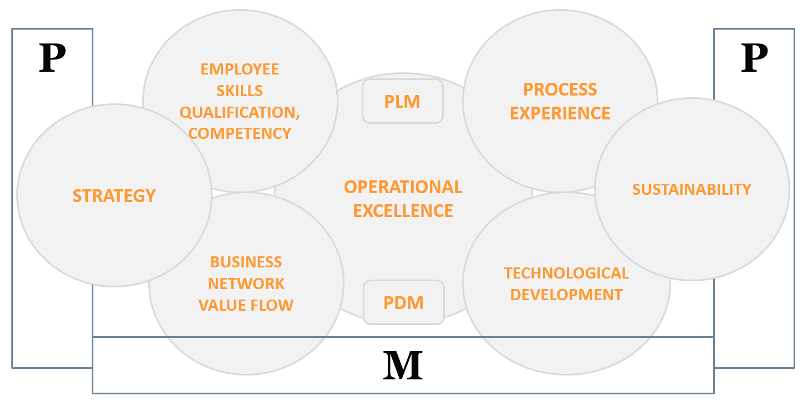

The product, from the mold equipment design PDM provides studies to eliminate the effects of functional faults in (Product Data Management) and product configuration.The measurement function network, which affects the error in the design capability,It focuses on the development of the technical infrastructure in terms of compatibility with the Product, Mold, Equipment CAD data.This situation, in all commissioned products,

PLM (Product Lifecycle Management) is committed to providing innovative solutions with the Lean Manufacturing philosophy on product safety issues by being monitored throughout the product life chain to the SOP, EOP and EOL stages.